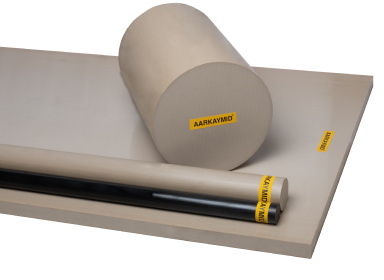

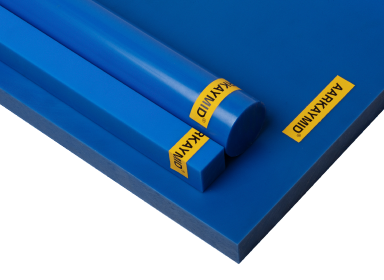

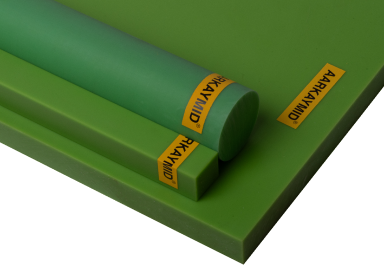

PEEK material (chemically known as Polyetheretherketone) is extruded in sheet, rod and tube that may use Victrex® PEEK or Solvay polymer as a raw material. PEEK stands out as a distinctive engineering thermoplastic with semi-crystalline properties, providing exceptional chemical compatibility as well. It is a high-performance engineering thermoplastic that is particularly suitable for high-temperature applications ranging from extremely low temperature to +250°C for long terms and to +310°C for short terms. This material exhibits excellent mechanical strength, stiffness, and hardness, along with good resistance to creep and dimensional stability. It possesses favourable electrical insulating and dielectric properties and demonstrates exceptional resistance to high-energy radiation. PEEK is highly recommended for use in industries such as aerospace, nuclear, chemical, automotive, and electrical. Classic Polymers provides PEEK material in various forms, including rods, sheets, tubes, and components, available in both natural and filled grades. PEEK plastic finds frequent application in environments involving hot water or steam due to its ability to uphold essential physical properties like flexural and tensile strength, even under harsh conditions. PEEK components are lighter, stronger and able to withstand severe application environments / operating conditions with high reliability which allows for very high up-time in service.

Send Message