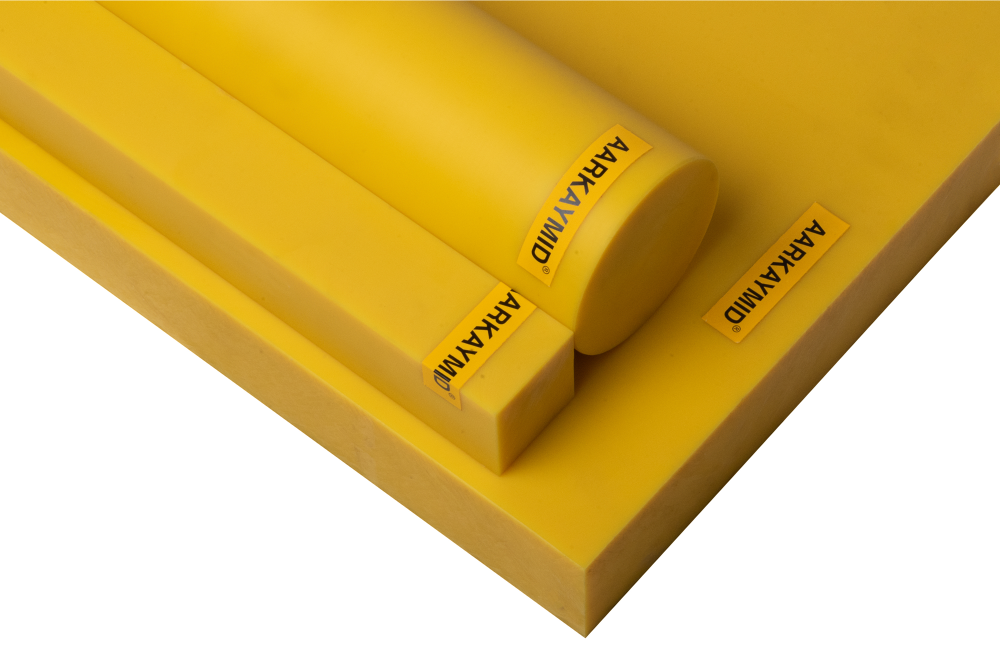

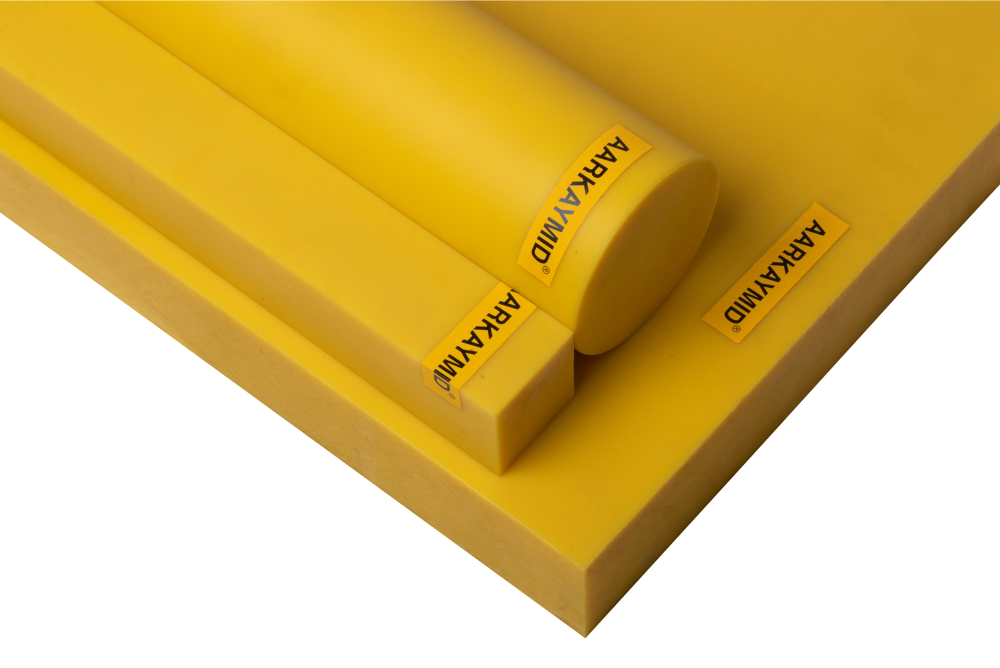

XF/XM

Easy to clean effect with AARKAYMID® XM/ XF, even large surface areas can be cleaned fast fluid runs off immediately, taking adherent substances and particles with it, due to the specially designed surface.

AARKAYMID® XF: for Food Processing Industry

The properties of AARKAYMID® XF provide a huge number of benefits in the food processing industry compared to conventional surfaces:

Antimicrobial action is also effective against Escherichia coli: AARKAYMID® XF prevents microbes like bacteria and fungi, which are present on the surface, from continuing to multiply. To achieve this antimicrobial effect, AARKAYMID® XF uses modern silver ion technology. The additive, which is non-toxic to humans, acts in a purely physical manner through the transfer of silver ions to prevent the growth of microbes. This process hinders the replication of bacterial strains. The bactericidal effects occur rapidly, a fact substantiated and certified by the Swiss company, Ciba Spezialitätenchemie AG in Basel. It has also been proven to be effective against Escherichia coli.

Shorter cleaning times: AARKAYMID® XF has an easy-clean effect which allows even large surface areas to be cleaned quickly. The surface has a nanoscale microstructure which produces a low surface tension of <18 mN/m. This ensures a remarkable reduction in the contact area for particles and fluids.

In addition, AARKAYMID® XF is superhydrophobic: fluid runs off immediately, taking adherent substances and particles with it, due to the specially designed surface.

Long service life: The surface of AARKAYMID® XF is resistant to chemicals and extremely scratch-resistant. It can withstand regular contact with standard disinfectants and cleaning agents in the long term. This means that the AARKAYMID® XF function is retained even after frequent cleaning.

AARKAYMID® XM: for Medical Facilities - Preventing multidrug-resistant bacteria

The prevention and control of multidrug-resistant bacteria in medical facilities are of great importance. Whenever weak patients come into contact with germs, their safe treatment and rapid recovery are put at risk. This is why hospitals, GP surgeries, and care homes demand stringent hygiene standards.

We have developed our antimicrobial wall covering AARKAYMID® XM in response to these specific requirements.

AARKAYMID® XM:

prevents the transmission of bacteria, viruses, mould, and even MRSA (methicillin-resistant Staphylococcus aureus) without the need for toxins or antibiotics. The surface is easily cleaned using standard cleaning agents.

AARKAYMID® XM therefore helps medical staff to maintain top hygiene standards in medical facilities.

AARKAYMID® XM has several advantages in comparison with conventional surfaces. Spacious areas, especially walls, doors, and crevices in tiled walls, offer an ideal environment for microbial colonisation. However, these surfaces require significant time and effort to maintain cleanliness and endure frequent exposure to disinfectants and cleaning agents in the long term.

AARKAYMID® XM has been specially designed with these requirements in mind:

Antimicrobrial action is also effective against MRSA: AARKAYMID® XM prevents microbes like bacteria and fungi, which are present on the surface, from continuing to multiply. To achieve this antimicrobial effect, we use modern silver ion technology. The additive, which is non-toxic to humans, acts in a purely physical manner - through the transfer of silver ions - to prevent the growth of microbes. This process hampers the reproduction of bacterial strains, with its bactericidal effects manifesting rapidly, as validated and certified by the Swiss company, Ciba Spezialitätenchemie AG in Basel. Its consistent efficacy against MRSA (methicillin-resistant Staphylococcus aureus) has also been substantiated through laboratory trials conducted by Ciba. Infection prevention: Effective strategies to prevent infections are crucial for clinics and hospitals, both medically and financially. Infections can result in patients having to be hospitalised for longer. In several European countries, treatments are billed based on a fixed rate per case. Extended hospital stays beyond this flat rate coverage can lead to expenses that exceed the predetermined charge, leaving the hospital unable to bill for these additional costs.

AARKAYMID® XM helps to prevent infection thanks to its antimicrobial action.

Shorter cleaning times: AARKAYMID® XM has an easy-clean finish which allows even large surface areas to be cleaned quickly. The surface has a nanoscale microstructure which produces a low surface tension of <18 mN/m. This guarantees a significant reduction in the contact area for particles and fluids. Furthermore, AARKAYMID® XM exhibits superhydrophobic properties, causing fluids to quickly bead off the surface along with any adhering substances and particles, thanks to its specially engineered surface.

Send Message