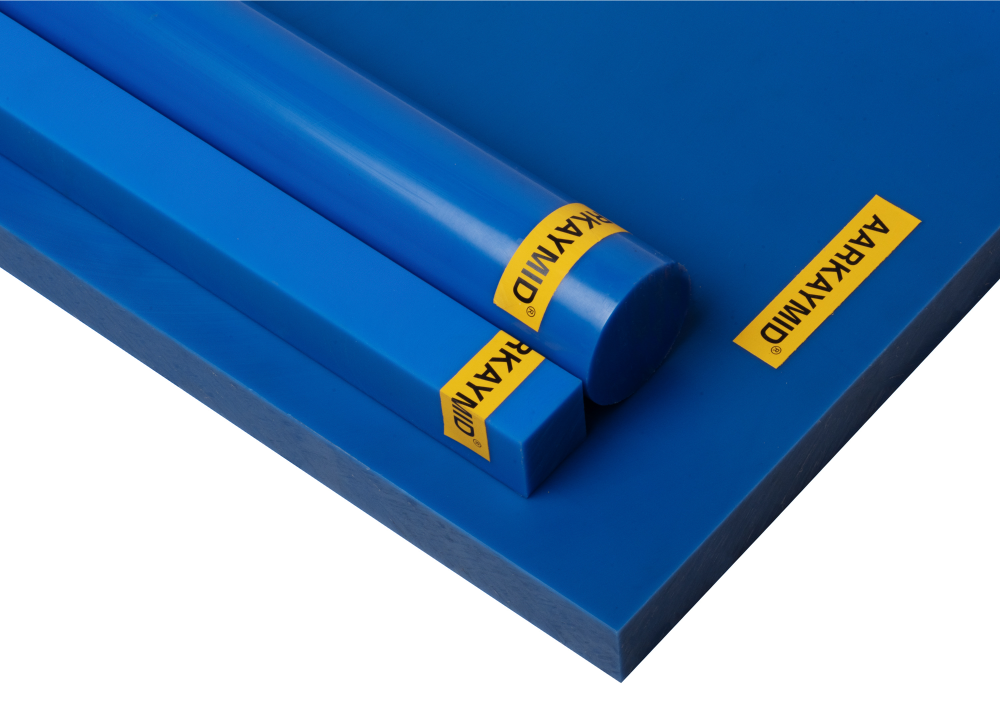

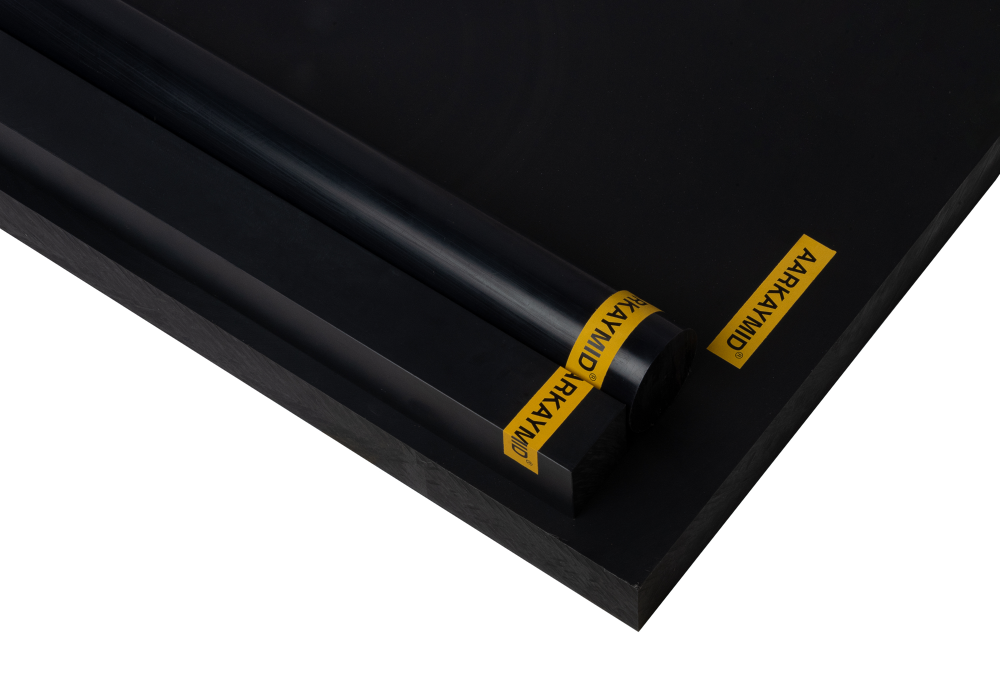

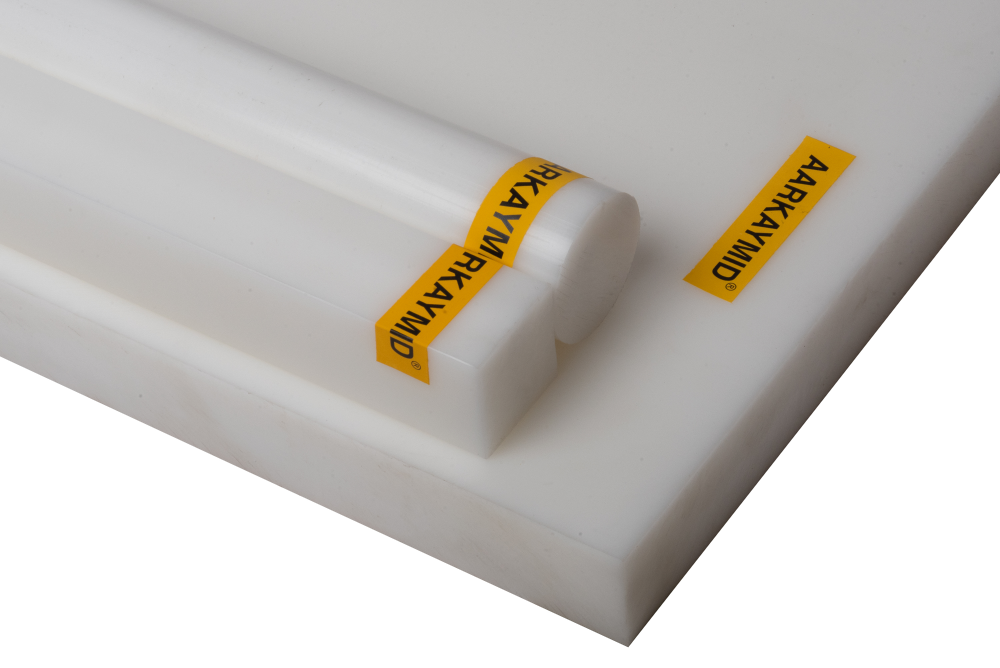

Cast Polyamide 6 (Cast Nylon 6 or PA 6) is one of the most versatile thermoplastics. Cast Nylon is a polymer characterised by its high molecular weight and its highly crystalline nature. With its unparalleled toughness, wear resistance, tensile strength, and lubricity, Nylon perfectly caters to the rigorous demands of modern engineers. This exceptional material serves as an ideal replacement for both ferrous and non-ferrous materials, offering numerous benefits such as noise reduction, reduced lubrication requirements, and minimised downtime. Nylon can be easily machined using standard general-purpose machinery, allowing for seamless integration into various applications. Through the incorporation of additives such as oil, solid lubricants, thermal stabilisers, or specialised fillers, the inherent properties of cast nylon materials can be finely tuned to suit specific applications, thus offering a diverse array of materials tailored to various needs. Furthermore, cast polyamide 6 stands out as an excellent alternative to metal, boasting fatigue resistance, noise reduction, corrosion resistance, and lightweight properties. PA 6 is a low maintenance material when compared with other metals such as iron, aluminium, brass and bronze. ‘PA 6 MC’ – Cast Heat Stabilised Grade PA 6 MC is ideal for a variety of bearing and structural applications. The grade of material has a distinct blue colour and is characterised by outstanding mechanical strength, rigidity, hardness, and toughness. The material also demonstrates exceptional sliding characteristics, excellent electrical insulation properties, and remarkable wear resistance. These attributes make PA 6 MC a preferred choice for applications such as gear wheels, racks, pinions, and custom components. For More Details Contact Classic Polymers and Resins

Send Message