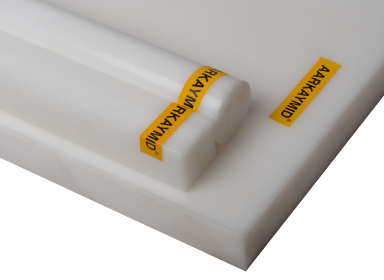

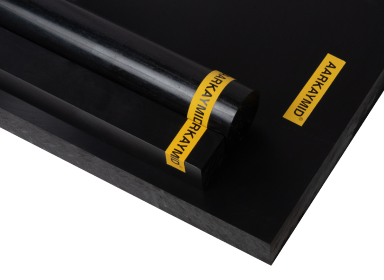

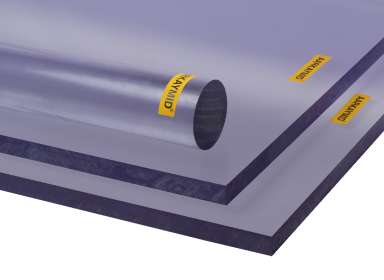

Extruded Polyamide / Nylon Plastic material, is available in standard stock shapes such as sheets, rods or tubes and can be machined to requirement. Extruded nylon can be of type PA 6, PA 12 or PA 66 and offers a balanced combination of performance and cost that provides end users with an optimal engineering plastic for standard applications or general purpose applications. Depending on the type, the extruded polymer differs in properties because of differences in molecular structure.These differences notably impact the mechanical properties and moisture absorption characteristics of the nylon. Nylon was the first engineering resin and is used in versatile applications ranging from electronic, marine, and automotive industries, to fibres for textiles. Extruded Nylon 6 / 66 has outstanding wear resistance and low frictional properties whilst also exhibiting very good temperature, chemical and impact properties. Additionally, this grade exhibits favourable electrical insulating ability and good chemical resistance. With a recommended working temperature of 85°C, it provides reliable performance in a wide range of applications.

Send Message